What are the sources of moisture inside a transformer?

Really high levels of moisture in the transformer are mainly caused by degradation of solid insulation and

ingress of moisture through ventilation.

The first cause is a consequence of the thermal cycles of the transformer that start/trigger chemical reactions

that produce water. However, the aging process of the paper insulator is considerably accelerated by the

presence of water inside the transformer.

For the safe operation of the transformer is therefore necessary that only dry air enters the conservator.

The relative humidity in the conservator depends on the transformer load cycle and by the ambient

temperature. Both these factors in fact induce temperature variations.

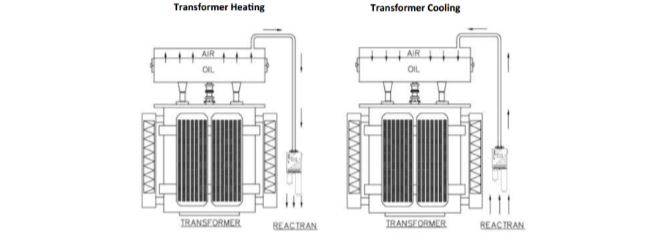

During the diurnal operating cycle of the transformer or when there is demand placed upon the transformer,

the temperature increases. Heat generated within the transformer causes a build-up of pressure and the air in

the conservator is pushed out of the transformer via the vent pipe.

During the night, the transformer cools down, hence the pressure inside the conservator drops and

atmospheric air is consequently driven into the transformer to restore the differential pressure.

This incoming air is then forced to pass through the silica gel transformer breather prior entering the

transformer. The breather will adsorb the incoming moisture providing a dry air blanket above the oil.

Moisture laden air could otherwise encroach into the oil and reach the sensitive part of the transformer, such

as the windings.

Using a Brownell breather, you will be using product developed over many years with input from both users

and transformer manufacturers.

And the consequences of moisture in distribution transformers?

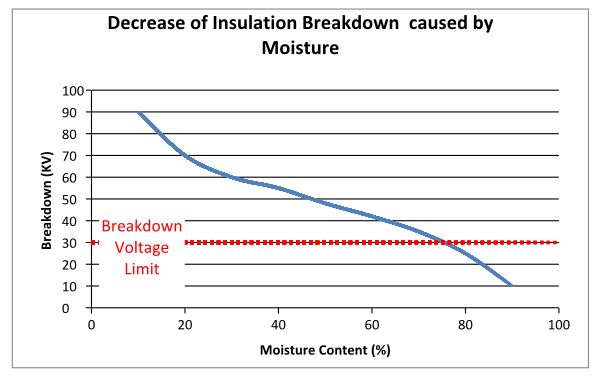

The main consequence of the presence of water in distribution transformers is a decrease in the insulation

breakdown strength. Excessive water content in the transformer oil may have catastrophic consequences.

If the breakdown voltage drops to the limit value of 30 KV, this can cause electrical breakdown and the

explosion of the distribution transformer.

Keeping a dry environment is important for the reliability of the transformer, whose life may be dramatically

reduced by the decreasing performance of the oil.

The water content inside the container depends on the oil characteristics (e.g. solubility) and it is also

influenced by the moisture content in the solid insulation.

When the transformer oil heats up, there is a higher percentage of moisture that dissolves in the oil.

During the thermal cycles lower electrical loading or winter/night conditions causes the oil temperature to

drop and the volume of oil decreases causing an inward flow in the conservator. The cooling process breaks

the Equilibrium Relative Humidity (ERH) between the oil and the moisture dissolved in it. The oil will therefore

release part of the moisture previously dissolved in it. As a consequence, due to the cooler temperature,

condensation may form onto the exposed inner surfaces of the conservator. During the next cycle, when the

oil heats up again a larger amount of water is dissolved in the oil, part of it already present in the conservator

and the rest driven inside the transformer by the pressure differential generated by the temperature variation.

There is also another important phenomenon that occurs inside a transformer, it is called “Transfer Effect”.

The water pressure differential causes the migration of moisture from one type of insulator to another. During

the cooling process, the moisture migrates from the oil into the solid insulation whereas when the

temperature rises, the paper insulation transfers the moisture to the liquid insulation.